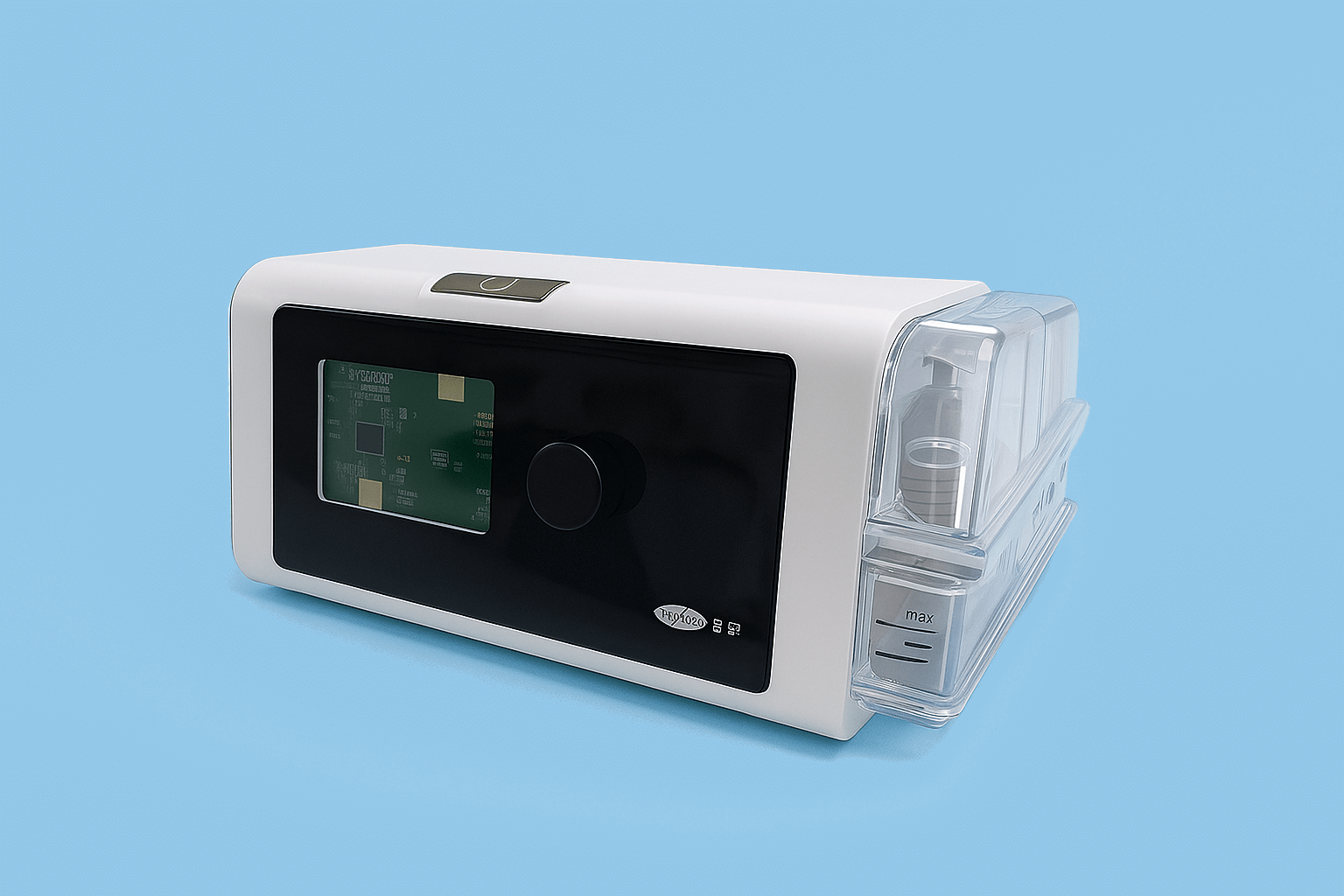

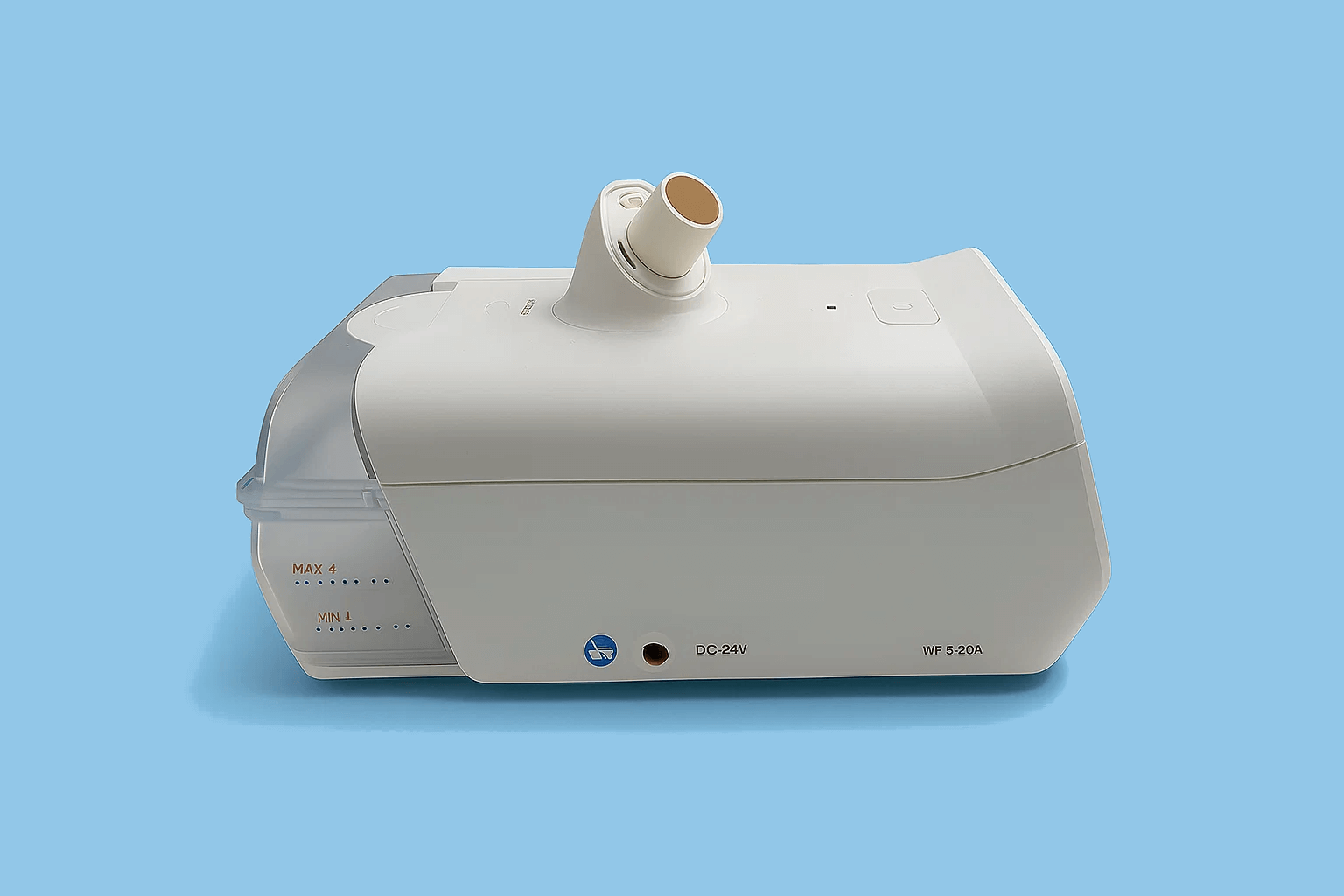

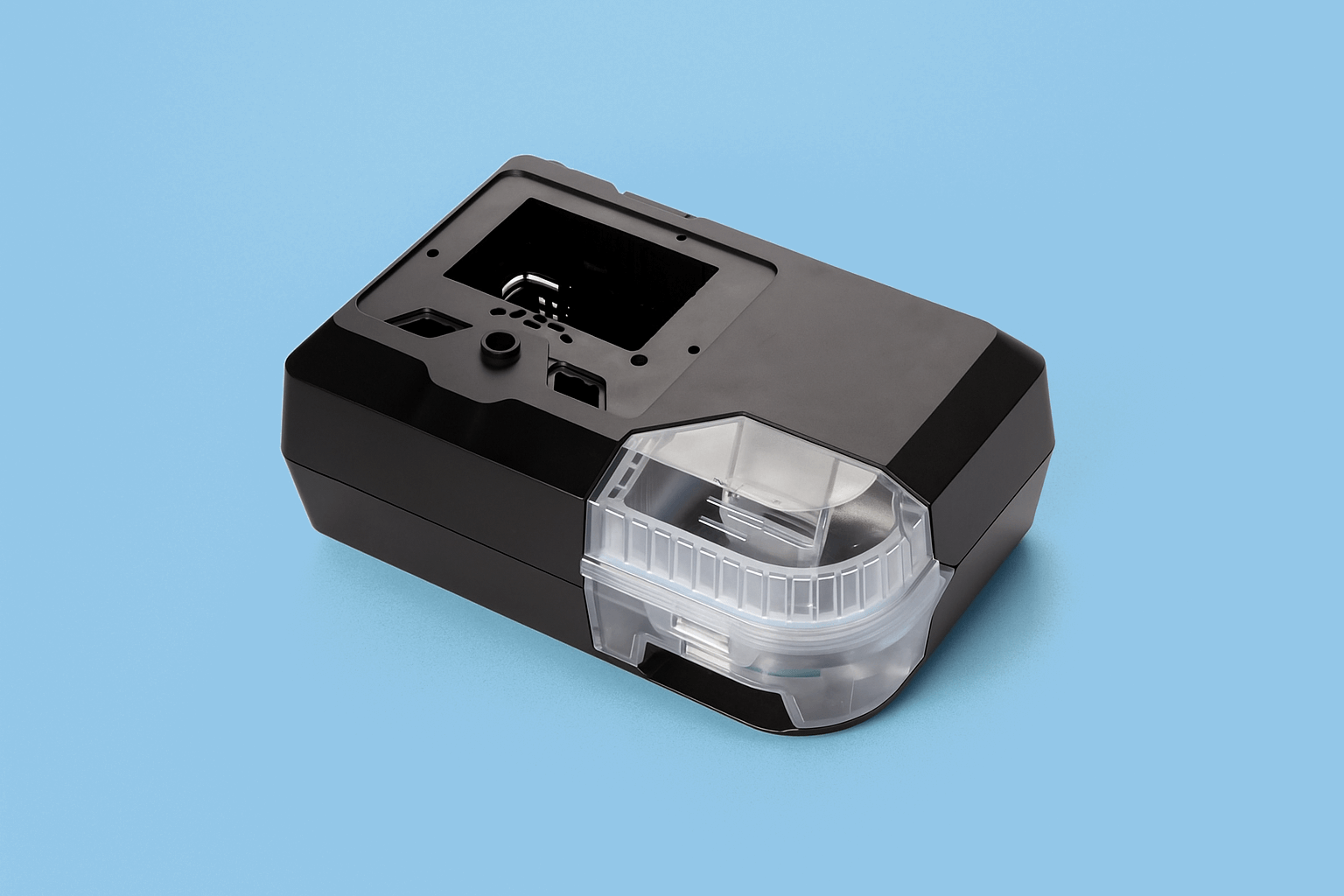

Global Medical Precision Injection Molding Sets New Standards

Contact us:asherxu@xrmould.com

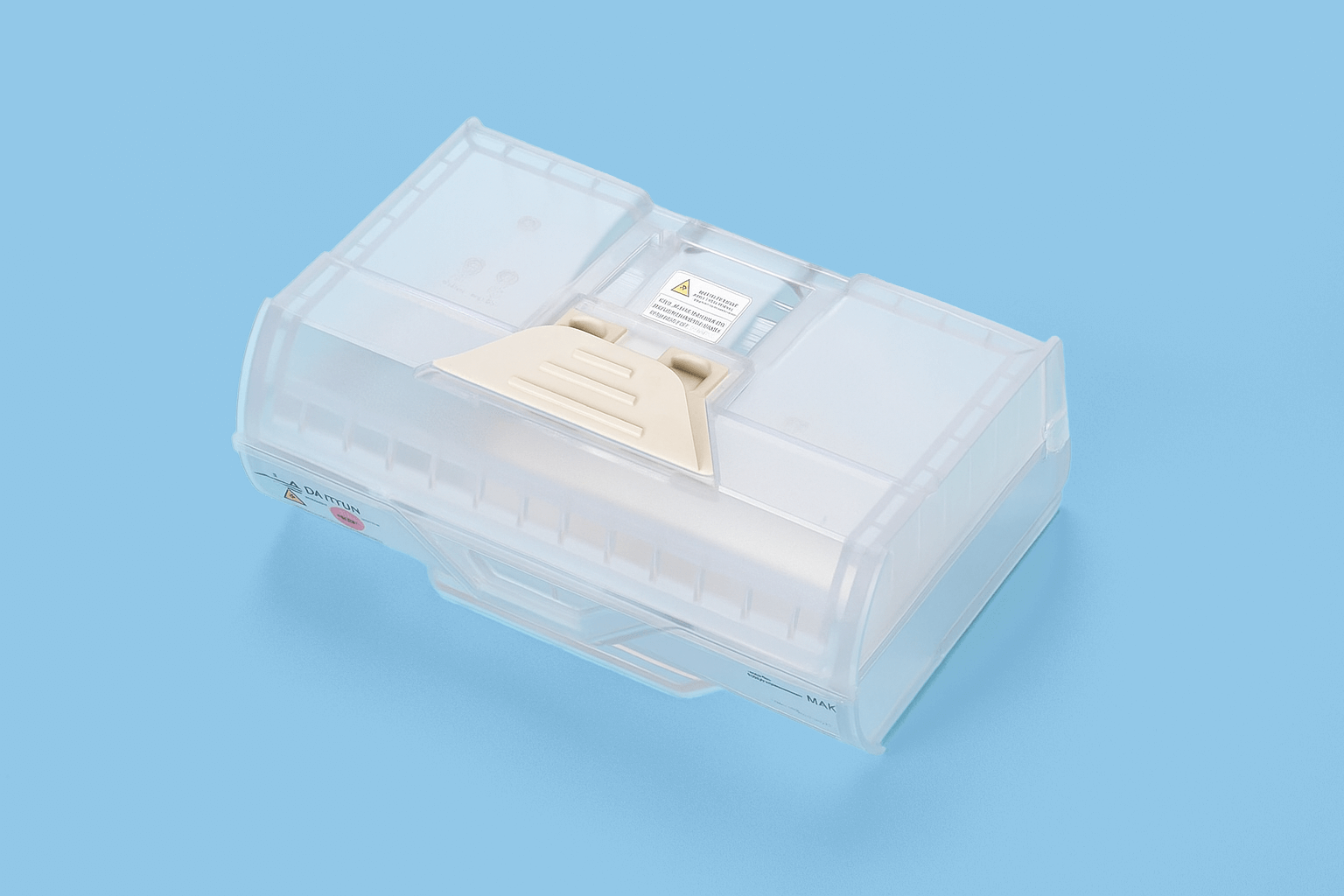

1600-ton Injection Molding Machine, Undertaking Large Medical Equipment Enclosure

Product maximum size:

2000*2000*800mm

High precision:

±0.01mm tolerance control

Production environment:

Class 100,000 cleanroom

What Can We Do?

The common choice of global customers

CONTACT US

CONTACT US