Core Advantages

Precision Stamping

• 800T Servo Press Cluster

• 0.1mm Ultra-Thin Sheet Processing

Electronic Device Shielding Covers

Connectors

Laser Cutting

• 12,000W Fiber Laser Cutter

• ±0.05mm Precision

Robotic Arm Structural Components

Cabinet Frames

Bending Forming

• 6-Axis Intelligent Bending Center

• 0.5° Angle Control

Industrial Equipment Housings

Energy Storage Enclosures

Welding Process

• Robotic TIG Welding

• Weld Strength >90% Base Material

Chassis Structures

Pipeline Systems

Surface Treatment

• Nano-Coating & Anodizing

• 2,000h Salt Spray Test Passed

Outdoor Communication Equipment

Marine Engineering Components

Intelligent Assembly

• Error-Proof Fixtures

• Vision Positioning System

Automated Production Line Integrated

Frameworks

Industry Solutions

Communication Equipment Sector

Pain Point Solved:

5G Base Station Heat Sink Flatness ≤0.2mm

XinRui Solution:

Aluminum Stretch Forming (Thickness 0.8-3mm)

High-Precision CNC Surface Finishing

Ceramic Coating for Enhanced Thermal Radiation

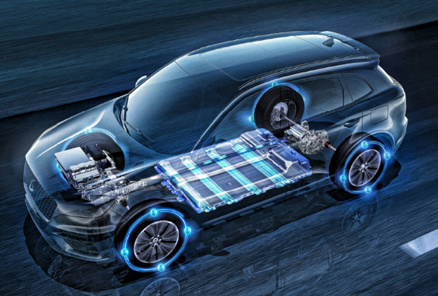

New Energy Sector

Breakthrough:

Power Battery Enclosure IP67 Compliance

XinRui Solution:

SUS304 Stainless Steel Laser Seam Welding

Bending R-angle ≤0.3mm Process

Triple-Protection Coating (-40℃~120℃ Resistance)

Industrial Automation Sector

Innovation:

Quick-Release Robot Protective Cover Design

Value Delivery:

Modular Snap-fit Mechanism (<30s Installation)

Noise-Damping Honeycomb Structure

Electrostatic Powder Coating (4H Wear Resistance)

Visualized Intelligent Manufacturing System

Digital Twin Workshop

Smart Scheduling System

Auto-optimized material utilization (Sheet utilization rate ≥92%)

Online Inspection System

Laser scanners monitor critical dimensions in real-time (CPK≥1.67)

Green Intelligent Manufacturing

Scrap recycling system reduces energy consumption by 35%

Equipment Type

TRUMPF Laser Cutter

AMADA Servo Press

HAN'S Laser Tube Cutter

Technical Parameters

12,000W / 6000x2000mm working area

800T pressure / 2000spm

±0.08mm / Tube diameter Ø20-200mm

Processing Range

Carbon steel / Stainless steel / Aluminum alloy

0.5-6mm metal sheets

Square tube / Round tube / Profiled tube

Quality Trust

Triple-Layer Quality Control System

Incoming Inspection

100% material verification via spectrometer (RoHS/REACH compliant)

Process Control

First-article 3D scanning at each station (0.02mm accuracy)

Final Assurance

Air-tightness/salt spray/drop tests (ISTA Standard)

Project Milestone

Industrial Robot Manufacturer Collaboration

Challenge:

Deliver 500 protective covers (with 20 complex bends) within 2 weeks

Solution:

• Developed multi-stage compound dies for process integration

• Deployed 3 laser cutters in parallel operation

Results:

Reduced lead time by 40% (18 days → 11 days)

Achieved 99.3% bend angle consistency

Annual cost savings exceeding ¥2 million

Service Response Commitment

Agile Manufacturing System

24/7 Technical Response

(Including DFM Analysis)

15-Day Rapid Prototyping

Dedicated Project Manager for End-to-End Coordination

CONTACT US

CONTACT US